Joris de Groot

Project

Collection: Weld bag

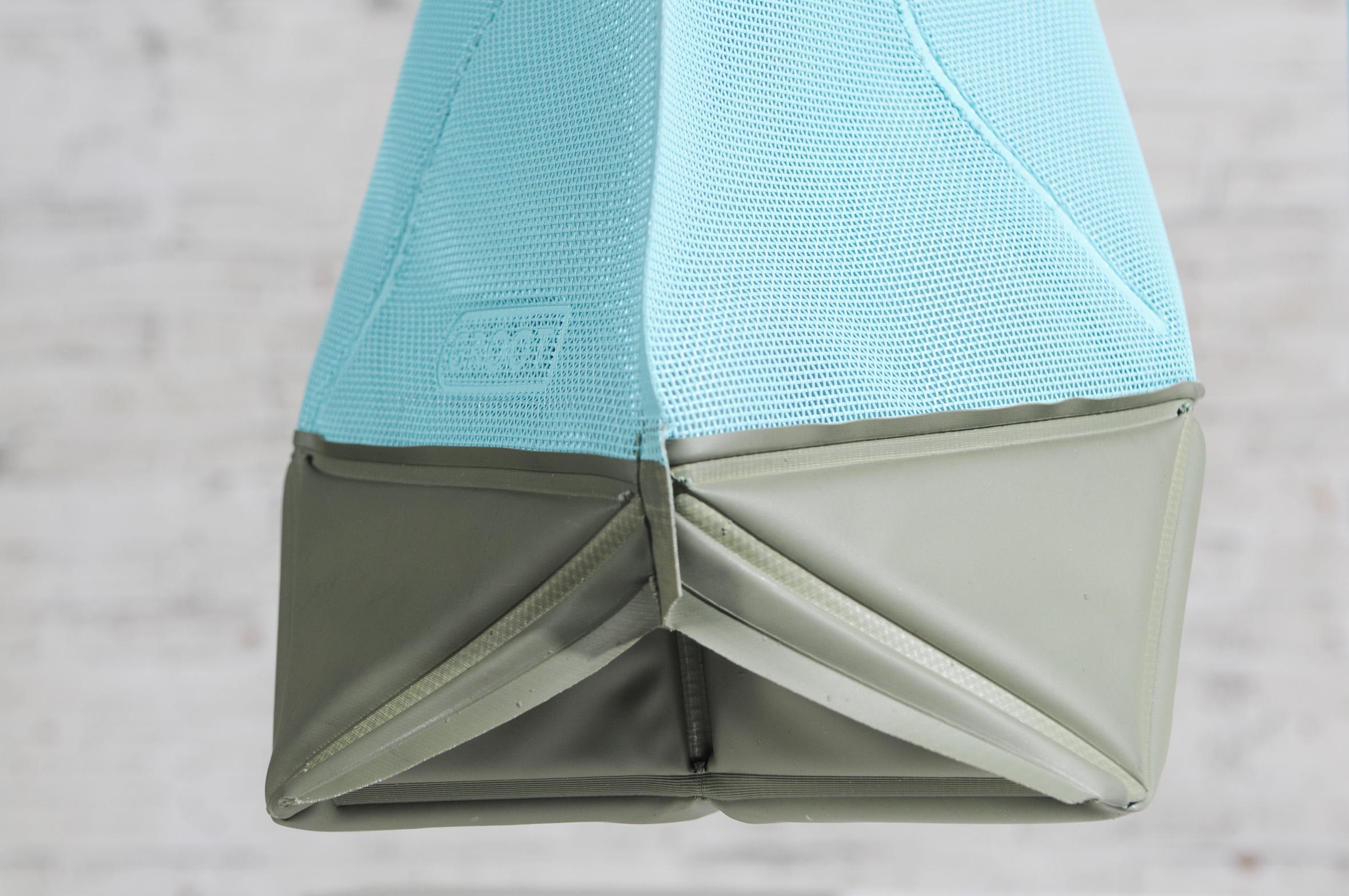

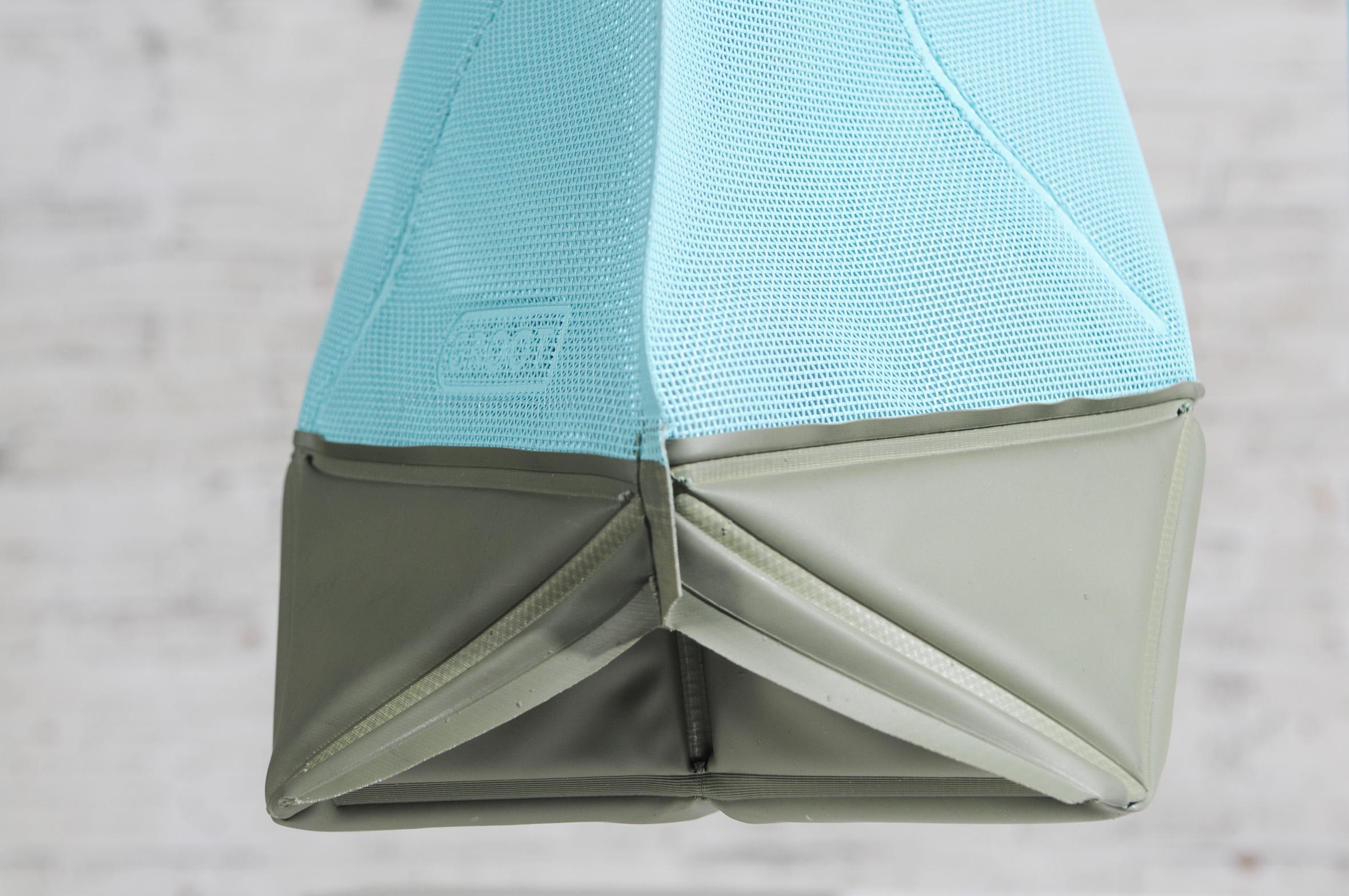

For my finals collection I collaborate with Dolfing Druten, a company that normally produces work clothes, rain gear and waterbeds. They work with all kinds of PVC material which they process using a high-frequency welding technique. I develop a line of bags consisting of a basic shopper, a sports bag, a beach bag and a laptop briefcase. This series took its shape from a folding technique that is commonly used for producing simple plastic shopping bags. This interesting way of constructing makes it possible to create my designs for industrial production in large numbers.

In addition to this I designed another series of bags “crease bag” in which I create volume by placing and welding certain folds in the bottom or sides of the bag. Besides producing and creating volume, to me it is also important that this technique presents me with visual details.

Production/materials

The materials I used for my Weld bag collection are PVC, synthetic netting and some leather for handles.

Over

Joris de Groot

Born 1988 in Nijmegen, the Netherlands. Joris was an intern at Chris Kabel Rotterdam from September to December 2012 and graduated in 2013 from the study Product Design ArtEZ in Arnhem.

Focus

Techniques, for construction and production, are my starting point. It’s my interest in techniques that brought me to plunge myself into knotting and twining during the first years of my studies in Arnhem. The same interest is at the root of my project to use existing industrial techniques and unused industrial capacity to create new products.